Copper Pipes & Tubes are among the most widely used materials in plumbing, heating and industrial applications. Known for their durability, corrosion resistance, and good heat conduction, cu pipes have been in great demand across industries. This is a proper guide to Copper Pipes and Tubes, which includes the difference, advantages, applications, and maintenance.

What is a Copper Pipe?

Copper Pipe is a type of cylindrical conduit made from copper, used primarily for transporting fluids and gases in residential, commercial, and industrial applications. Unlike copper tubing, Copper Pipes are usually rigid and need fittings to be installed, although they are very tough, corrosion-resistant, and can support high pressure, so they are used for plumbing, heating, ventilating, air conditioning systems, and gas distribution systems.

If you desire high-quality copper pipe for your project. Sagar Prakash is the leading copper pipe manufacturer in India.

What is a Copper Tube?

Copper Tube is a cylindrical hollow section made from copper, commonly used in plumbing, HVAC, and industrial applications. It is known for being good at conducting heat and electricity, resistant to corrosion, and long-lasting. Copper tubes come in different forms such as soft and hard ones, which are flexible enough to fit into any type of installation. They have been extensively applied in water supply systems, refrigeration, and gas pipes owing to their performance and longevity.

Is there any Difference Between Copper Pipe and Copper Tube?

Although Copper Pipes & Tubing are often used interchangeably, there are some key differences between them:

- Flexibility: Copper tubing is more flexible and can be bent to fit into tight spaces, whereas these pipes are rigid and require fittings for direction changes.

- Thickness and Strength: Cu pipes tend to be thicker and stronger, so suitable for high-pressure use. Copper tubing, particularly soft tubing, is thinner and utilized in low-pressure systems.

- Applications: Copper Pipes are widely utilized in plumbing, gas piping, and HVAC systems, whereas copper tubing is used for refrigeration, medical gas systems and specialized industrial uses.

- Installation: Copper Pipes are easier to install with fewer fittings because of their flexibility, while copper tubing needs threaded or soldered joints.

What are the Advantages ?

Copper Tubes & Pipes have many benefits compared to other piping materials. Here are some key benefits:

-

Corrosion Resistance

Copper Pipe are very resistant to corrosion, and they will last long while minimizing the risk of leaks and contamination in water supply systems.

-

Durability

It is a strong material capable of withstanding extreme pressure and temperature, making it suitable for numerous applications such as high-temperature and high-pressure conditions.

-

Safety and Health Benefits

Copper is a non-toxic substance that doesn’t release harmful chemicals into the water system, and thus ensures safe and pure drinking water. Moreover, copper has antimicrobial functions that prevent bacteria growth within the pipes.

-

Outstanding Thermal Conductivity

The high thermal conductivity of copper makes it an ideal material for applications involving heating, including radiant heating and HVAC systems.

-

Easy Installation and Maintenance

These pipes are simple to install, cut and solder. They need little maintenance and possess a long lifespan, cutting down on costs in the long term.

-

Eco-Friendly and Recyclable

Copper is an eco-friendly substance that can be reused without suffering from a diminishment of properties and thus suitable for plumbing, as well as for industrial usage.

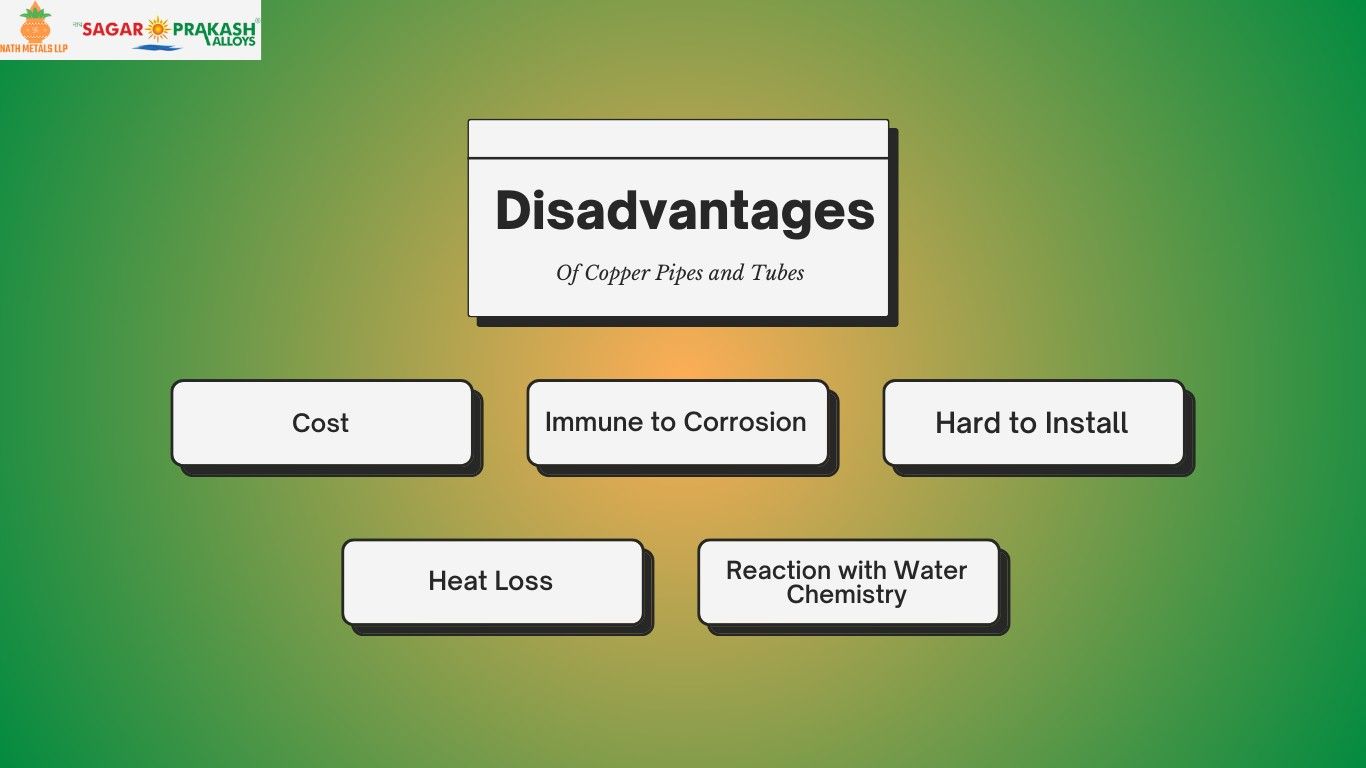

What are the Disadvantages?

While the Pipe offer many benefits, they also have some drawbacks, here are some:

-

Cost

Cu pipes cost more than other options such as PVC or PEX. As material and installation prices are high, they could be less desirable for cost-conscious applications.

-

Susceptibility to Corrosion

Although copper in general is noncorrosive, it is not immune to some types of corrosion such as pitting corrosion, which will lead to leaks and system failure.

-

Rigid and Hard to Install

In contrast to PEX tubing, Copper Pipes are inflexible and need to be carefully cut, installed, and fitted, which is more time-consuming and time-consuming.

-

Heat Loss

Due to its high thermal conductivity it loses heat more quickly than other materials, which may require additional insulation in heating systems to improve energy efficiency.

-

Reaction with Water Chemistry

In regions where water is extremely acidic or alkaline, such pipes can get corroded with time, and leakage and contamination can occur.

Applications of Copper Pipes & Tubes

Copper Tubes & Pipes are used in a wide range of applications across various industries. Some common uses include:

Plumbing Systems

Copper Pipe are widely used in residential, commercial, and industrial plumbing systems for water supply and distribution.

HVAC and Refrigeration

Cu tubing is essential in HVAC systems, air conditioning units, and refrigeration systems due to its thermal conductivity and resistance to corrosion.

Gas Lines

They are also normally used in distributing natural gas and propane due to their long life and strength at withstanding high-pressure applications.

Medical Gas Systems

Copper Pipe are used by hospitals and healthcare centers for the distribution of medical gas, which provides a clean and consistent supply of oxygen and other medical gases.

Fire Sprinkler Systems

Copper Pipes are used in fire sprinkler systems due to their high heat resistance and durability, ensuring efficient water flow during emergencies.

Industrial Applications

They are being used in desalination processes, chemical process industries, as well as in heat exchangers because they possess superior heat and corrosion-resistant properties.

What are the Benefits of Implementing Copper Pipes in a Compressed Air System?

Copper Pipes are a superior option for compressed air systems owing to their rust free, and degradative properties, which ensure long-term lifespan. Their leak proof joints through soldering or brazing assure permanent air pressure. Copper, with a smooth internal surface, reduces pressure drops and friction to a minimum, which improves airflow efficiency and saves energy. It is also capable of withstanding high temperatures, does not need much maintenance, and is light in weight, facilitating easy installation, particularly in narrow areas.

How Long Can Copper Pipes Last Long?

- Copper Pipe last for between 50 to 70 years, depending on the quality of water, surroundings, and maintenance.

- While the thickest type K Copper Pipes will last the longest, the thinner type L and M pipes will have shorter lifespans.

- Corrosion, pH levels, and excessive water pressure may have some effect on longevity, but if well maintained, copper piping is a strong and dependable option for different systems.

Selecting The Right Copper Pipes & Tubes

When choosing the right Pipes and tubes, consider the following:

- Application: Select the right type depending on the use (e.g., plumbing, heating and air conditioning, gas lines).

- Size and Thickness: Provide the appropriate pipe size and thickness to manage the desired pressure and flow rate.

- Budget: Type M pipes are affordable, whereas Type K and L provide greater durability for heavy-duty applications.

- Compliance and Standards: Ensure the pipes meet industry standards and certifications for safety and performance.

Read more about types here – Different Types Of Copper Pipe Explained!

Conclusion

Copper Tubes & Pipes are the preferred option for plumbing, HVAC, gas distribution, and industrial use because of their performance, safety and longevity. Knowing the advantages, and uses of Copper Pipes will assist in making the proper product choice for your particular requirement. With adequate care and maintenance, cu pipes can be a reliable and long-term solution for piping systems.