As a leading name in the forging industry, Sagar Prakash Alloys stands out as a premier choice among forging suppliers in India. Renowned for our commitment to excellence, we specialize in delivering high-quality forged products tailored to meet diverse industrial needs. Our team of skilled professionals works in state-of-the-art facilities to ensure that we not only meet but exceed our clients' expectations, whether precision, durability, or adherence to stringent standards.

What is forging?

Forging is a metalworking process where the metal is heated until it becomes malleable and then shaped through compressive forces. The required temperature for forging varies based on the metal type. Depending on the metal and design requirements, hot or cold forging can be used. Forging can be done manually or with machines like press forges or drop hammers to achieve the desired shape.

Materials for Forging Metal

The selection of forging materials is primarily influenced by application requirements and the desired properties of the final product. At Sagar Prakash Alloys, we offer a diverse range of forging materials tailored to various industrial needs. For more detailed information about our forging material grades, please don't hesitate to contact us. We are dedicated to providing high-quality materials that precisely meet your specific requirements.

- Nickel Forgings

- Monel Forgings

- Inconel Forgings

- Hastelloy Forgings

- Titanium Forgings

- Tantalum Forgings

- Duplex Steel Forgings

- Super Duplex Steel Forgings

Types of Forging Process

Open Die Forging:

In open die forging, metal undergoes deformation between flat dies that lack a pre-cut shape, allowing for greater flexibility and suitability for larger, less intricate shapes.

Closed Die Forging:

Also known as impression die forging, this method involves placing the metal between dies with a pre-cut shape, and the metal is then hammered or pressed into the desired form, resulting in more complex and precise parts.

Roll Forging:

Roll forging employs cylindrical rolls to deform the metal, and these rolls may have specific contours to create desired shapes. This process is often used for long, cylindrical parts such as shafts and rings.

Upset Forging:

This process involves increasing the cross-sectional area of the metal by compressing its length, often used to create thicker sections or heads on parts.

Hot Forging :

Hot Forging is a process where metal is heated and shaped under force. This enhances its mechanical properties and allows for the creation of complex shapes. It is widely used in various industries.

Cold Forging :

Cold Forging is a metal shaping process where room-temperature (or slightly elevated) metal is forced into a desired shape using high compressive pressure. This pressure typically comes from specialized machines like presses or hammers, not manual force. Unlike hot forging, cold forging doesn't require heating the metal to high temperatures.

Precision Forging:

Precision forging employs close tolerances and often requires additional machining. It is used to achieve high accuracy and surface finish, making it suitable for critical components.

Net Shape Forging:

Net shape forging aims to produce parts with minimal or no need for additional machining, thereby reducing material waste and increasing efficiency in the manufacturing process.Isothermal Forging:

In isothermal forging, the metal is heated and maintained at a constant temperature throughout the process. This helps in achieving better material flow & reduces tool wear.

Electromagnetic Forging:

Electromagnetic forging uses electromagnetic fields to control and enhance deformation. This technique can be applied to various forging methods for improved precision.

Forging Capabilities

| Flat bar blocks | up to 27" width and 15,000 lbs. |

| Cylinders and sleeves | up to 50" maximum O.D. and 65" maximum length |

| Discs and hubs | up to 50" diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84" maximum O.D. and 40" maximum length |

| Rounds, shafts and step shafts | up to 144" maximum length and 20,000 lbs. |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

Our Diverse Range of Forged Shapes

Forged Bars

Forged Circles

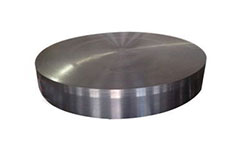

Forged Discs

Forged Ring

Forged Block

Forged Shaft

Forged Bushing

Forged Gear Blank

To buy forging components at best price & urgent delivery, please mail to [email protected], As we have Our Dealer, Supplier, distributors & direct sales representatives in all over globe who will help you to buy forged parts & will resolve your queries

Advantages of forging

- Creates much stronger and more durable parts than those produced through other methods.

- Pressure applied during the forging process results in a denser, tighter grain structure, making the finished parts more resistant to wear and tear.

- Forged parts are less likely to fail under load or stress, making them ideal for critical applications.

- It is also a highly sustainable manufacturing process.

- It also generates very little waste, as any scrap material can be recycled and used again.

At Sagar Prakash Alloys, we are committed to providing our customers with high-quality forging products that meet their needs and exceed their expectations. Our team of experts has decades of experience in the industry and works closely with our clients to ensure that every order is fulfilled to their exact specifications.

The forging industry is an exciting and rapidly evolving field, and at Sagar Prakash Alloys, we are proud to be at the forefront of this market. We are dedicated to providing our customers with the best possible products and services, and we look forward to continuing to grow and evolve with the industry in the years to come.

We Deliver Forging Parts all over World

We export most of Forgings to countries like

Lebanon, Tunis, Ethiopia, Cote d'Ivoire, Bahrain, Accra, Lilongwe, Khartoum, Tripoli, Thailand, Porto-Novo, Austria, Malaysia, Cape Town, Bhutan, Brazil, Belarus, Germany, Botswana, Spain, Australia, Pretoria, Oman, Netherlands, Vietnam, Monrovia, South Korea, Trinidad & Tobago, Gaborone, Tunisia, Namibia, Belgium, Turkey, Kazakhstan, South Sudan, Mexico, Yamoussoukro, Dakar, Algiers, Egypt, Uganda, Hungary, Niamey, Jordan, Slovakia, Madagascar, Algeria, Serbia, Pakistan, South Africa, Addis Ababa, Norway, Venezuela, Kenya, Ghana, Central African Republic, Algeria, Poland, Mozambique, Iran, Banjul, Hong Kong, Bissau, Luanda, Bulgaria, Sweden, Saudi Arabia, Cameroon, Switzerland, Yemen, Chile, Gambia, Costa Rica, Seychelles, Russia, Lesotho, Peru, Nigeria, Croatia, Somalia, Canada, Macau, Portugal, Rwanda, Taiwan, Victoria, Lomé, Argentina, Maputo, Iraq, Bangui, Mogadishu, China, Angola, Italy, Benin, United Arab Emirates, Comoros Congo, Chile, Port Louis, Eswatini, Czech Republic, Singapore, Japan, Mongolia, Iran, Puerto Rico, Moroni, Mbabane, Poland, Sudan, France, Lithuania, Brazzaville, Greece, Sri Lanka, Qatar, Kigali, Bangladesh, Afghanistan, Togo, Colombia, Kuwait, Abuja, Tunisia, Bolivia, Gabon, Israel, United States, Mexico, Estonia, Zimbabwe, Azerbaijan, Eritrea, Denmark, Nepal, Romania, Ecuador, Oyala, United Kingdom, Indonesia, Ukraine, Ireland, Guinea-Bissau, Libya, Nigeria, Guinea, Senegal, Antananarivo, Liberia, Zambia, Tibet, Tanzania, New Zealand, Malawi, Equatorial Guinea, Mauritius, Philippines, India, Morocco, Conakry, Finland, Niger, Sao Tome and Principe, Malabo, Djibouti.

We supply most of Forgings to city like

Vadodara(Gujarat), Thane(Maharashtra), Gurgaon(Haryana), Visakhapatnam(Andhra Pradesh), Navi Mumbai(Maharashtra), Chandigarh(Punjab), Rajkot(Gujarat), Faridabad(Haryana), Hyderabad(Andhra Pradesh), Bhopal(india), Indore(Madhya Pradesh), Ludhiana(Punjab), Bengaluru(Karnataka), Pune(Maharashtra), Howrah(West Bengal), Surat(Gujarat), Kolkata(West Bengal), Haryana(india), Noida(Uttar Pradesh). Secunderabad(Hyderabad), Ahmedabad(Gujarat), Pimpri-Chinchwad(maharashtra), Coimbatore (Tamil Nadu), Ernakulam(Kerala), Chennai(Tamil Nadu), New Delhi, Thiruvananthapuram(Kerala), Mumbai (maharashtra).