Sagar Prakash Alloys is one of the leading nickel 200 forging suppliers and stockists in the global market. We specialize in providing high-quality UNS N02200 forging products to various industries, including chemical and petrochemical. Our products are known for their excellent corrosion resistance.

Nickel 200 is made of ferromagnetic, commercially pure (99.6%) nickel. It has excellent mechanical and thermal properties, making it highly suitable for forging applications. The forging process of Nickel 200 enables the material to be shaped into various industrial components, including valves, piping, tanks, and heat exchangers.

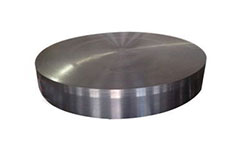

Forging nickel 200 requires a high-temperature forging technique, with the temperature range typically starting at around 1200°C up to 950°C. This allows the material to be shaped in various forms, including bars, discs & sheets. The Nickel 200 melting point for forging is approximately 1435°C. At these high temperatures, Nickel 200 Forging has excellent flexibility, which allows it to be easily forged into its final shape.

Nickel 200 Forging Suppliers in India, Buy Nickel N02200 Forged Block at Best Price, Ni Alloy 200 Custom Forged Parts, ASTM B564 UNS N02200 Seamless Rolled Ring Forging.

Nickel Alloy 200 Forging Bush, ASME SB564 Nickel 200 Alloy Forged Discs, WNR 2.4066 Forged Shafts, 200 Nickel Forged Ring Manufacturer, Ni 200 Forged Bar, Alloy 200 Forging Components Stockist in Mumbai.

We offer ASTM B564 UNS N02200 Forging in different shapes and sizes, including Shafts, bars, sheets, plates, blocks, and forged rings. Each of our products is custom-made to meet the unique requirements of our customers. Also, Our Nickel 200 Forging prices depend on several factors, including the product's size, quantity, and complexity. At Sagar Prakash Alloys, we offer competitive pricing, ensuring that our customers get the best value for their money.

Advantages of selecting nickel 200 for forging

Exceptional Corrosion Resistance: Ideal for diverse environmental conditions.

Superb Thermal and Electrical Conductivity: Ensures efficient heat and electricity

transfer.

Low Gas Content: Enhances toughness and formability.

High Melting Point: Withstands elevated temperatures.

Resistance to Acids: Suitable for corrosive environments.

Versatile Applications: Offers durability and reliability in various forging

processes.

Uses of Nickel 200 Forging:

Alloy 200 Forging is widely used in applications requiring high temperatures and excellent corrosion resistance. It is often used to manufacture heat exchangers, reaction vessels, piping systems, and other equipment in chemical processing plants. Its low magnetic permeability and high electrical conductivity make it ideal for use in the electronics and aerospace industries.

Sagar Prakash Alloys is known for its high-quality products. Our extensive experience and expertise in the field make us the preferred choice for clients across various industries. Contact us today to learn more about our high nickel alloy forging solutions.

Nickel 200 Forgings Specification

| Standard | ASTM B564, ASME SB564 |

| Specification | DIN, ASTM, BS and all International Standards |

| Flat bar blocks | up to 27" width and 15,000 lbs. |

| Cylinders and sleeves | up to 50" maximum O.D. and 65" maximum length |

| Discs and hubs | up to 50" diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84" maximum O.D. and 40" maximum length |

| Rounds, shafts and step shafts | up to 144" maximum length and 20,000 lbs. |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

Nickel UNS N02200 Forgings Availability

Nickel 200 Forged Gear Blank

Nickel N02200 Forged Circles

ASTM B564 UNS N02200 Forged Discs

Nickel Alloy 200 Forged Ring

Nickel 200 Forged Block

Nickel 200 Forged Shaft

Nickel 200 Forged Bars

Alloy 200 Forged Bushing

Equivalent Grades of Nickel 200 Alloy Forgings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel Alloy 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

Nickel 200 Forgings Chemical Properties

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel Alloy 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Nickel Alloy 200 Forgings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

To buy Nickel 200 Forgings At best price & urgent delivery please mail to [email protected], As we have Our Dealer, Supplier, distributors & direct sales representatives in all over globe who will help you to buy Nickel 2.4066 Forgings & will resolve your queries

Other types of Nickel 200 Forgings Ready Stock

- Nickel DIN 2.4066 Forged Discs

- Nickel Alloy UNS N02200 Forged Circular Plates

- Nickel Alloy 200 Impression Die Forging

- Nickel DIN 2.4066 Forged Shafts

- Nickel Alloy NW 2200 Open Die Hammer Forging

- Nickel Alloy 2.4066 Forged Seamless Rings

- Nickel 200 Open Die Forging Manufacturer

- Nickel 200 Forged Hollow Bars

- Nickel 200 Forged Flat Bars

- Nickel 200 Forged Blocks

- Nickel UNS N02200 Forged Circles

- Nickel UNS N02200 Press Forging

- Nickel DIN 2.4066 Upset Forging

- Nickel Alloy 200 Impression die drop forging

- Nickel 200 Seamless Rolled Forging

- Nickel 200 Forging Discs Exporter

- Nickel 200 Compression Forging Manufacturer In Mumbai

- ASTM B564 Nickel 200 Circle

- ASME SB 564 Nickel 200 Open die hammer forging

- Nickel UNS N02200 Hot Forging

- Nickel 200 Cold Forging Manufacturer In India

- 200 Nickel Forging Bar Supplier

We Deliver ASTM B564 Nickel N02200 Forgings all over World

We export most of 200 Nickel Forgings to countries like

Sudan, Tanzania, Togo, Tunisia, Uganda, Zambia, Algiers, Luanda, Porto-Novo, Gaborone, Bangui, Moroni, Brazzaville, Yamoussoukro, Malabo, Oyala, Mbabane, Addis Ababa, Banjul, Accra, Conakry, Bissau, Algeria, Benin, Botswana, Cameroon, Central African Republic, Comoros Congo, Cote d'Ivoire, Djibouti, Equatorial Guinea, Eritrea, Eswatini, Ethiopia, Guinea, Guinea-Bissau, Lesotho, Liberia, Madagascar, Malawi, Mauritius, Mozambique, Niger, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Somalia, South Sudan, Monrovia, Tripoli, Antananarivo, Lilongwe, Port Louis, Maputo, Niamey, Chile, Afghanistan, Israel, Lithuania, Austria, New Zealand, Ecuador, Estonia, Qatar, Bhutan, Australia, Abuja, Kigali, Dakar, Victoria, Mogadishu, Pretoria, Cape Town, Khartoum, Lomé, Tunis, Saudi Arabia, Gambia, Brazil, Mongolia, United States, China, Switzerland, Sweden, Netherlands, Bulgaria, Peru, Puerto Rico, Morocco, Malaysia, Nigeria, Germany, Jordan, Ireland, Mexico, Canada, Spain, Philippines, Iran, Trinidad & Tobago,Tunisia, Czech Republic, Pakistan, Lebanon, Taiwan, Indonesia, Thailand, Chile, Oman, Bolivia, Mexico, Poland, Iraq, Singapore, France, Serbia, Libya, Denmark, Vietnam, Japan, Hong Kong, South Africa, Kuwait, Russia, Angola, Norway, Yemen, Nepal, Finland, Gabon, Macau, Tibet, Slovakia, Ghana, Belgium, Namibia, Kenya, Kazakhstan, Iran, Hungary, Sri Lanka, Turkey, Costa Rica, Nigeria, Zimbabwe, Greece, Azerbaijan, Ukraine, Colombia, Poland, Argentina, Italy, South Korea, Croatia, Belarus, United Kingdom, India, Algeria, Bahrain, Egypt,United Arab Emirates, Portugal, Bangladesh, Romania, Venezuela.

We supply most of Nickel 200 Forgings to city like

Hyderabad(Andhra Pradesh), Secunderabad(Hyderabad), Chennai(Tamil Nadu), Haryana(india), Rajkot(Gujarat), Ludhiana(Punjab), Faridabad(Haryana), Indore(Madhya Pradesh), Gurgaon(Haryana), Mumbai (maharashtra), Pune(Maharashtra), New Delhi, Navi Mumbai(Maharashtra), Thane(Maharashtra), Pimpri-Chinchwad(maharashtra), Thiruvananthapuram(Kerala), Coimbatore (Tamil Nadu), Chandigarh(Punjab), Ahmedabad(Gujarat), Kolkata(West Bengal), Visakhapatnam(Andhra Pradesh), Surat(Gujarat), Bhopal(india), Vadodara(Gujarat), Ernakulam(Kerala), Howrah(West Bengal), Bengaluru(Karnataka), Noida(Uttar Pradesh).