Top Round Bar Suppliers in Mumbai | High-Quality Bars and Rods

- Stainless Steel 303 Bars

- Stainless Steel 304/304L Bars

- Stainless Steel 310/310S Bars

- Stainless Steel 316 Bars

- Stainless Steel 316L Bars

- Stainless Steel 316Ti Bars

- Stainless Steel 347/347H Bars

- Stainless Steel 904L Bars

- Stainless Steel 410 Bars

- Stainless Steel 420 Bars

- Stainless Steel 17-4PH Bars

- Stainless Steel XM19 Bars

Tantalum Bars

Aluminium Bars

Copper Bars

Bronze Round Bars

Aluminium Bronze Bars

Leaded Tin Bronze Bars (C92200)

Silicon Bronze Bars (C65000)

Different Types of Metal Round Bar Stock

Round Bar

Flat Bar

Hex Bar

Leading Round Bar Suppliers in India

We are one of the leading round bar suppliers in India, and our products are ISO certified and tested for quality to meet the customers' exact requirements. See all on our Certificates

Round Bar Specification

Round Bar Weight Calculator

Quickly find the weight of round bars with our weight calculator.

Check Round Bar Size Chart

| Imperial Sizes | Metric Sizes |

| Diameter (inches) | Diameter (mm) |

| 1/16" | 1.59 mm |

| 3/32" | 2.38 mm |

| 1/8" | 3.18 mm |

| 5/32" | 3.97 mm |

| 3/16" | 4.76 mm |

| 7/32" | 5.56 mm |

| 1/4" | 6.35 mm |

| 5/16" | 7.94 mm |

| 3/8" | 9.53 mm |

| 7/16" | 11.11mm |

| 1/2" | 12.70 mm |

| 9/16" | 14.29 mm |

| 5/8" | 15.88 mm |

| 3/4" | 19.05 mm |

| 7/8" | 22.23 mm |

| 1" | 25.40 mm |

| 1 1/8" | 28.58 mm |

| 1 1/4" | 31.75 mm |

| 1 3/8" | 34.93 mm |

| 1 1/2" | 38.10 mm |

| 1 5/8" | 41.28 mm |

| 1 3/4" | 44.45 mm |

| 2" | 50.80 mm |

| 2 1/4" | 57.15 mm |

| 2 1/2" | 63.50 mm |

| 2 3/4" | 69.85 mm |

| 3" | 76.20 mm |

| 3 1/2" | 88.90 mm |

| 4" | 101.60 mm |

| 4 1/2" | 114.30 mm |

| 5" | 127.00 mm |

| 6" | 152.40 mm |

| Bar Shape Types | Sizes |

| Forged Bar |

Length: 3 to 6 Meters

Size:130 – 500 mm |

| Hex Bar |

Finish: Shot Blast & Drawn, Cold Drawn, 240 Grit Belt Polished

Length: 3 to 6 Meters

Size:5 to 60 mm Tolerance: h12, h11, h13 |

| Square Bar |

Tolerances : h12, h11,h13

Finish :Polish & Black, Bright Size :5 to 70mm Length :3 to 6 Meters |

| Threaded Bar |

Length :3/ 2/4 meter

Thread Type : Class-2 & Class-1 Diameter : M6 to M48 Condition : Threading, Cold Drawn Length Tolerance : -0 / +200 mm Thread Condition : Fully Threaded |

| Flat Bar |

Finish: Shot Blasted, HRAP, Polished

Thickness: 0.5 to 200 mm Width: 1.5 to 250 mm Length: 0.5to 7.0 meter |

Manufacturer of steel bars in accordance with AMS/ ASME/ ASTM standard

Manufacturing Capabilities

Our advanced manufacturing capabilities enable us to provide:

- Custom lengths, diameters, and surface finishes

- Precision machining for tight tolerances

- Heat-treated bars for enhanced strength and durability

- Polished and pickled finishes for specific applications

The following checks are performed on round bars and documented in the Test Certificate as per customer specifications

- First, we perform a Surface Inspection using Magnetic Particle Inspection to spot any defects.

- Next, we conduct Positive Material Identification through XRF analysis to ensure the material composition is correct.

- Dimensional Verification comes next, where we check every piece using Vernier calipers and Go/No-Go gauges.

- Visual Inspection is carried out to detect any surface irregularities.

- The Upset Forging Test assesses the material's deformation and strength during the forging process.

- We then check the Nonmetallic Inclusion Rating (NMIR) to evaluate the purity and levels of inclusions in the material.

- Macrostructure Testing allows us to examine the internal structure for consistency.

- Microstructure Phase Analysis helps us identify the grain structure and how phases are distributed within the material.

- In Grain Size Analysis, we assess how refined and uniform the grains are.

- Ultrasonic Testing is employed to detect any internal flaws or discontinuities that may be present.

- We conduct a Radioactivity Test to confirm material safety and adhere to compliance standards.

- Finally, Gas Analysis looks at the levels of oxygen, nitrogen, and hydrogen contained within the metal to monitor its quality.

Key Benefits of Our Round Bars

- Corrosion Resistance: Ideal for extreme environments, including marine and chemical exposure.

- Durability: Long-lasting performance, even under high stress.

- Precision: Crafted with exact dimensions for seamless integration.

- Reliability: Backed by strict quality checks and certifications.

Application and Uses of Round Bars

Our round bars are used in a wide range of industries, from medical screws to construction

Why Choose Sagar Prakash Alloys as Steel Round Bar Supplier ?

Advanced Manufacturing:

- State-of-the-art CNC rolling mills and precision cutting technology.

- Custom cuts, grooves, and branding as per client requirements.

Rigorous Quality Assurance:

- In-house lab with spectral analysis, ultrasonic testing, and hardness checks.

- Third-party inspections (SGS, TÜV) supported

Transparent Pricing & Terms:

- Competitive pricing based on material, volume, and finish.

- Bulk discounts (MOQ: 5 Tons)

- Payment: LC, T/T, Credit for trusted partners.

- Global shipping (FOB/CIF) | 15–30 Days Lead Time.

Sustainability Commitment:

- Eco-friendly production with 80% recycled scrap.

- REACH & RoHS compliant.

Global Logistics & Support

Packaging: Anti-rust coating + wooden crates for safe transit.

Inventory: Real-time stock updates for 50+ grades.

24/7 Support: Dedicated account managers + live chat.

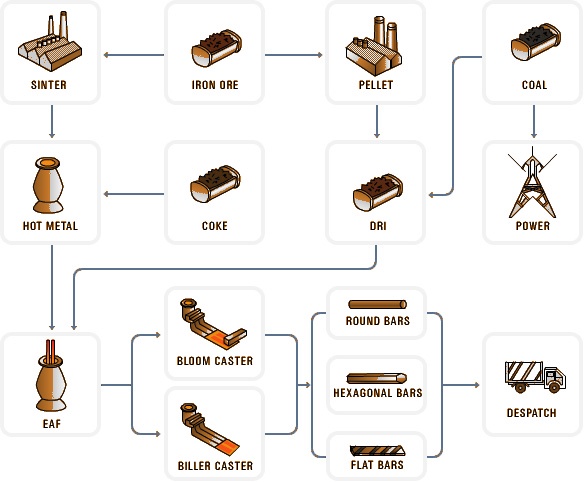

Round Bar Manufacturing Process

Buy hot and cold-rolled round bars online in custom sizes and cut lengths— delivered anywhere

Sagar Prakash Alloys: Industrial Round Bar Solutions

Your Trusted Partner for Precision-Crafted, High-Performance

Round Bars

✅ 33+ Years of Expertise in Metal Bar Manufacturing

✅ ISO 9001:2015 Certified

✅ 10,000+ Tons Monthly Production Capacity

✅ Tailored Solutions for Automotive, Aerospace,

and

Construction Industries

Downloads: