Sagar Prakash Alloys is a leading supplier and stockist of tantalum forgings. Tantalum is a rare, corrosion-resistant metal in high demand in the aerospace, medical, and chemical industries. Our tantalum forgings come in various shapes and sizes and are known for their exceptional strength and durability.

What is Tantalum Forging?

Tantalum forging is when tantalum metal is heated to a high temperature and then shaped using forging techniques like hammering or pressing. This process creates tantalum products, including sheets, bars, and forgings. Tantalum is a highly resistant metal, making it ideal for use in high-temperature and corrosive environments.

We offer tantalum forging at the most competitive prices to our clients. We also provide outstanding customer service, which includes technical advice, quick response & timely deliveries. Contact us today for a Tantalum Forging quote for your specific requirements.

Tantalum Forgings Supplier in India, UNS R05255 Forged Bar, Tantalum Forgings price, Custom Forged Tantalum Parts, Buy Tantalum Forged Block at best price, Tantalum Alloy Crank Shaft Forging.

Tantalum Alloy R05200 Forged Discs, Tantalum Grade R05252 Seamless Rolled Ring Forging, Tantalum Forged Shafts, Ta UNS R05400 Forged Rings Manufacturer, Tantalum Forging Components Stockist in Mumbai.

Tantalum Forging Process

The tantalum forging process involves shaping tantalum metal into different forms using compression or hammering. The temperature range for forging tantalum typically falls between 1400°C and 2300°C, depending on the desired form and shape. Tantalum has a high melting point of about 2996°C, making it an ideal material for high-temperature applications.

We offer UNS R05200 Forgings in various shapes and sizes to meet our clients' specific needs. We also provide forged tantalum rods, bars, discs, shafts, and blocks in standard sizes and customized shapes and sizes based on client requirements.

Uses of Tantalum Forging

Tantalum Alloy Forging is used in several high-temperature industrial applications. It is commonly used in aerospace industries, chemical processing, power generation, nuclear engineering, and medical implants. Tantalum Forging components are famous for their excellent corrosion-resistant properties, high melting point, and durability.

If you are looking for reliable Tantalum Forgings, look no further than Sagar Prakash Alloys. With years of experience in the industry and a team of expert engineers and technicians, we provide our clients with the highest quality tantalum forgings that meet the most stringent industry standards.

Tantalum Forgings Specification

| Specification | ASTM, BS and all International Standards |

| Flat bar blocks | up to 27" width and 15,000 lbs. |

| Cylinders and sleeves | up to 50" maximum O.D. and 65" maximum length |

| Discs and hubs | up to 50" diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84" maximum O.D. and 40" maximum length |

| Rounds, shafts and step shafts | up to 144" maximum length and 20,000 lbs. |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

Types of Tantalum Forgings

Tantalum Forged Block

Tantalum Forged Shaft

Tantalum Forged Circles

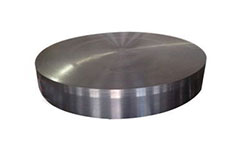

Tantalum Forged Discs

Tantalum Forged Ring

Tantalum Forged Bars

Tantalum Forged Bushing

Tantalum Forged Gear Blank

Equivalent Grades of Tantalum Forgings

| ASTM Grade | UNS Number | ISO Grade |

|---|---|---|

| R05200 | R05200 | TA1 |

| R05400 | R05400 | TA2 |

| R05252 | R05252 | TA3 |

| R05255 | R05255 | TA4 |

Tantalum Forgings Chemical Properties

| Grade | C | O | N | H | Fe | Mo | Nb | Ni | Si | Ti | W |

| R05200 (%,Max) | 0.01 | 0.015 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 |

| R05400 (%,Max) | 0.01 | 0.03 | 0.01 | 0.0015 | 0.01 | 0.02 | 0.1 | 0.01 | 0.005 | 0.01 | 0.05 |

Tantalum Forgings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength | Elongation |

| 16.60 g/cm3 | 2996 °C | psi – 25000, MPa – 172 | psi – 15000, MPa – 103 | 25 % |

To buy Tantalum Forgings At best price & urgent delivery please mail to [email protected], As we have Our Dealer, Supplier, distributors & direct sales representatives in all over globe who will help you to buy Tantalum Forgings & will resolve your queries

Other types of Tantalum Forgings Ready Stock

- Tantalum Forged Flat Bars

- Tantalum UNS R05200 orged Blocks

- Tantalum Forged Circles Manufacturer In Mumbai

- Tantalum Forged Discs

- Tantalum UNS R05240 Forged Circular Plates

- Manufacturer Of Tantalum Impression Die Forging

- Tantalum Forged Shafts

- Tantalum R05200 Open Die Hammer Forging

- Tantalum Forged Seamless Rings

- Tantalum Open Die Forging

- Tantalum Forged Hollow Bars

- Tantalum Seamless Rolled Forging Manufacturer In India

- Tantalum UNS R05200 Hot Forging

- Tantalum Forging Bar Supplier

- Tantalum Forging Discs Exporter

- Tantalum Compression Forging

- Tantalum Circle Forging

- Tantalum UNS R05200 Press Forging

- Tantalum Open die hammer forging

- Tantalum R05400 Upset Forging

- Tantalum Impression die drop forging Manufacturer

- Tantalum Cold Forging

We Deliver Tantalum Forgings all over World

We export most of Tantalum Forgings to countries like

Philippines, Rwanda, Norway, Singapore, Chile, Australia, United Kingdom, Morocco, Algiers, New Zealand, Somalia, Qatar, Algeria, Liberia, Ecuador, Bangladesh, Bhutan, Nigeria, Malabo, Spain, Macau, Mauritius, Slovakia, Sweden, Greece, Niamey, Addis Ababa, Benin, Libya, Germany, Croatia, Comoros Congo, Guinea-Bissau, Kigali, Niger, Yemen, Romania, Chile, Austria, Maputo, Dakar, Madagascar, Zimbabwe, Brazil, Bahrain, Guinea, Cameroon, Uganda, Sao Tome and Principe, Tibet, Malawi, Belarus, Mozambique, Mexico, South Korea, Bissau, Azerbaijan, Pretoria, Central African Republic, Poland, Bangui, Jordan, Hungary, Portugal, Tunis, Mbabane, Tripoli, Canada, Mexico, India, Switzerland, Tunisia, Russia, Hong Kong, Czech Republic, Serbia, Iraq, Oman, Trinidad & Tobago, China, France, Lilongwe, Gaborone, Cote d'Ivoire, Gabon, Kazakhstan, Luanda, Thailand, Malaysia, Zambia, Taiwan, Ethiopia, South Africa, Venezuela, Lithuania, Japan, Seychelles, Italy, South Sudan, Monrovia, Banjul, Port Louis, Algeria, Ukraine, Tanzania, Mogadishu, Argentina, Pakistan, Victoria, Angola, Ghana, Lebanon, United Arab Emirates, Nigeria, Turkey, Lesotho, Belgium, Kuwait, Djibouti, Bolivia, Israel, Nepal, Sudan, Mongolia, Brazzaville, Puerto Rico, Togo, Poland, Antananarivo, Indonesia, Equatorial Guinea, Estonia, Egypt, Finland, Vietnam, Saudi Arabia, Netherlands, Porto-Novo, Moroni, Yamoussoukro, United States, Colombia, Gambia, Eritrea, Conakry, Oyala, Costa Rica, Peru, Iran, Accra, Iran, Namibia, Lomé, Afghanistan, Abuja, Senegal, Cape Town, Bulgaria, Botswana, Tunisia, Khartoum, Sri Lanka, Ireland, Denmark, Kenya, Eswatini.

We supply most of Tantalum Forgings to city like

Indore(Madhya Pradesh), Gurgaon(Haryana), Mumbai (maharashtra), Navi Mumbai(Maharashtra), Thane(Maharashtra), Pimpri-Chinchwad(maharashtra), Thiruvananthapuram(Kerala), Coimbatore (Tamil Nadu), Chandigarh(Punjab), Ahmedabad(Gujarat), Kolkata(West Bengal), Visakhapatnam(Andhra Pradesh), Surat(Gujarat), Bhopal(india), Vadodara(Gujarat), Ernakulam(Kerala), Howrah(West Bengal), Bengaluru(Karnataka), Hyderabad(Andhra Pradesh), Secunderabad(Hyderabad), Chennai(Tamil Nadu), Faridabad(Haryana), Pune(Maharashtra), New Delhi, Haryana(india), Rajkot(Gujarat), Ludhiana(Punjab), Noida(Uttar Pradesh).